J5 Pre-Heater Clogging

Heat Transfer | Controls Logic| Parameters | Materials Science Chemical Compatibility | Operations

October 2024 – July 2025

System Engineering

Project Scope and Background

Spontaneous polymerization of printing resin in the pre-heater renders the machine inoperable.

Affecting ~1500 machines.

Expensive replacement part and extensive technical service visit.

Operational savings goal: ~$120,000 yearly.

Research and Root Cause Analysis

I led a Cross-Functional Root Cause Investigation effort, involving mechanical design, system engineering, software, chemical compatibility, materials science and metallurgic research.

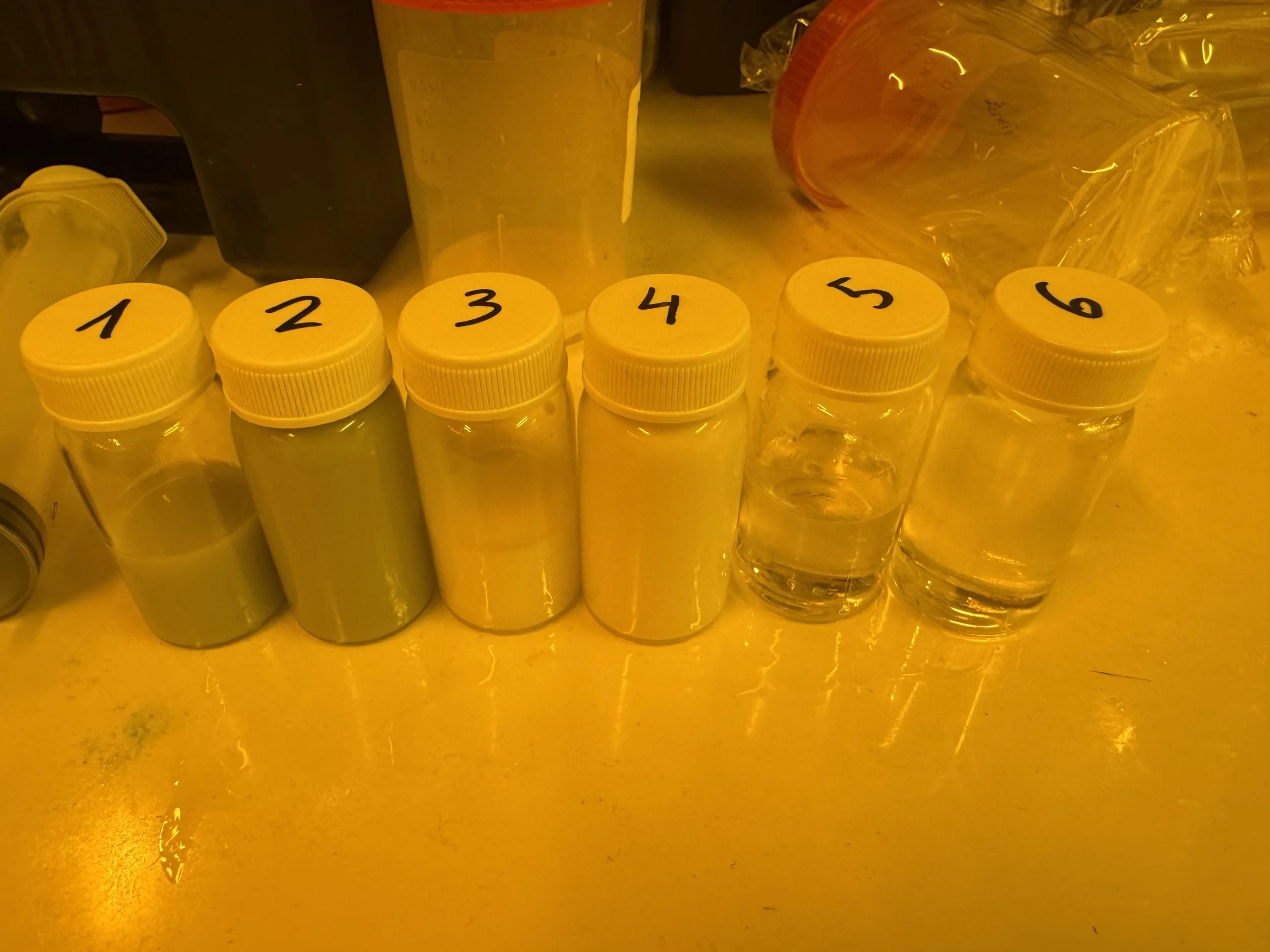

Printing Materials Root Cause was identified as a specific chemical component in the printing resin, contributing to spontaneous polymerization.

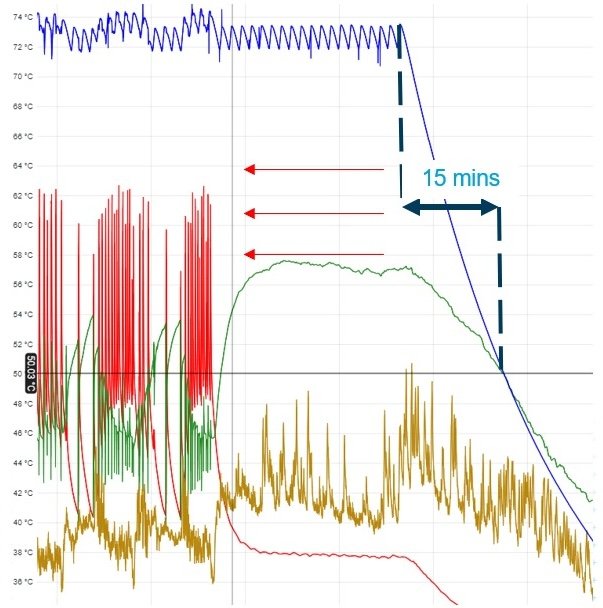

System-level Root Cause was identified as unoptimized temperature control logic, contributing to premature aging of the unprinted resin in the system, leading to unwanted polymerization.

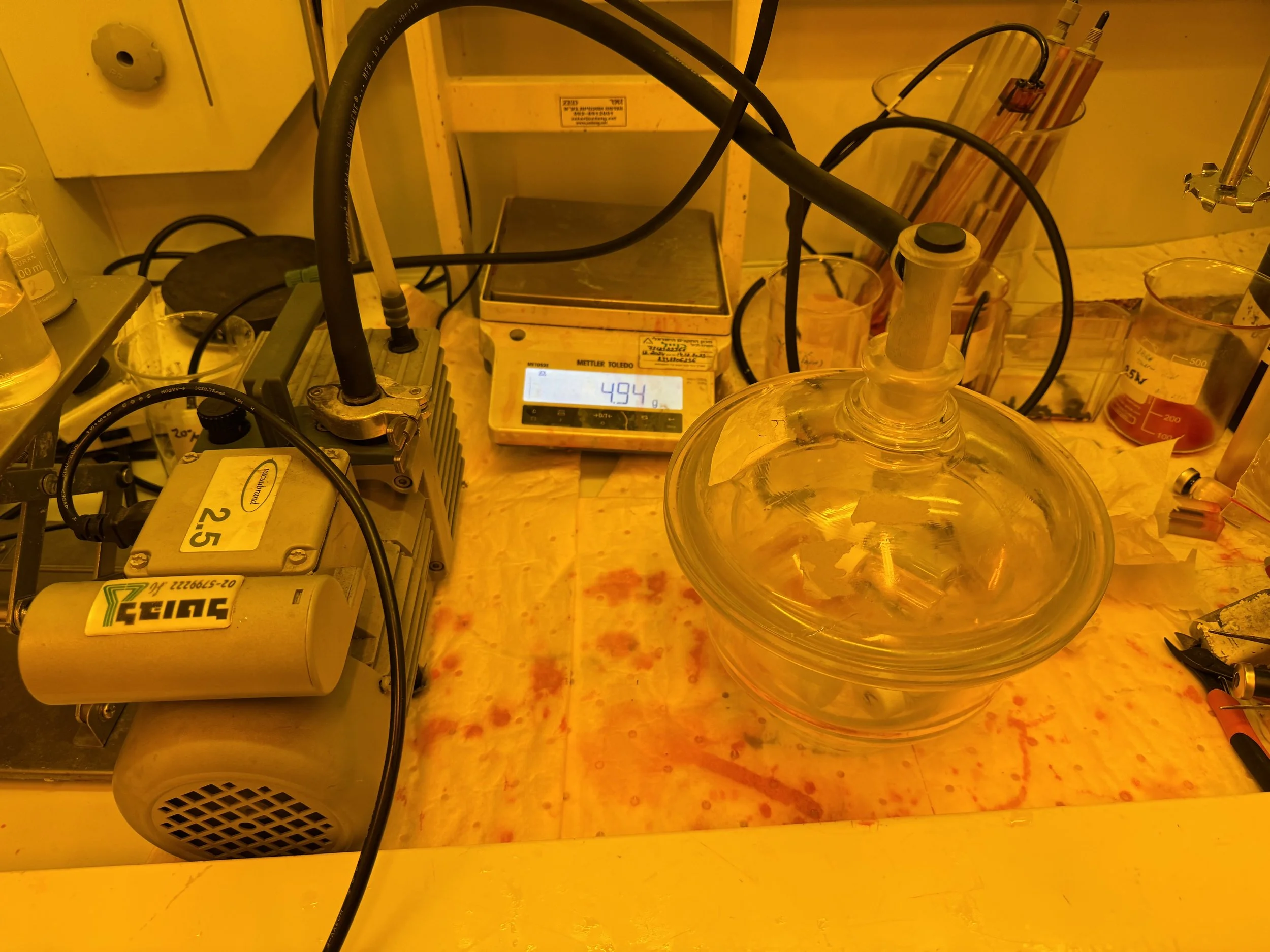

Mechanical level Root Cause was identified as compromised pre-heater resin path design, accelerating the polymerization process.

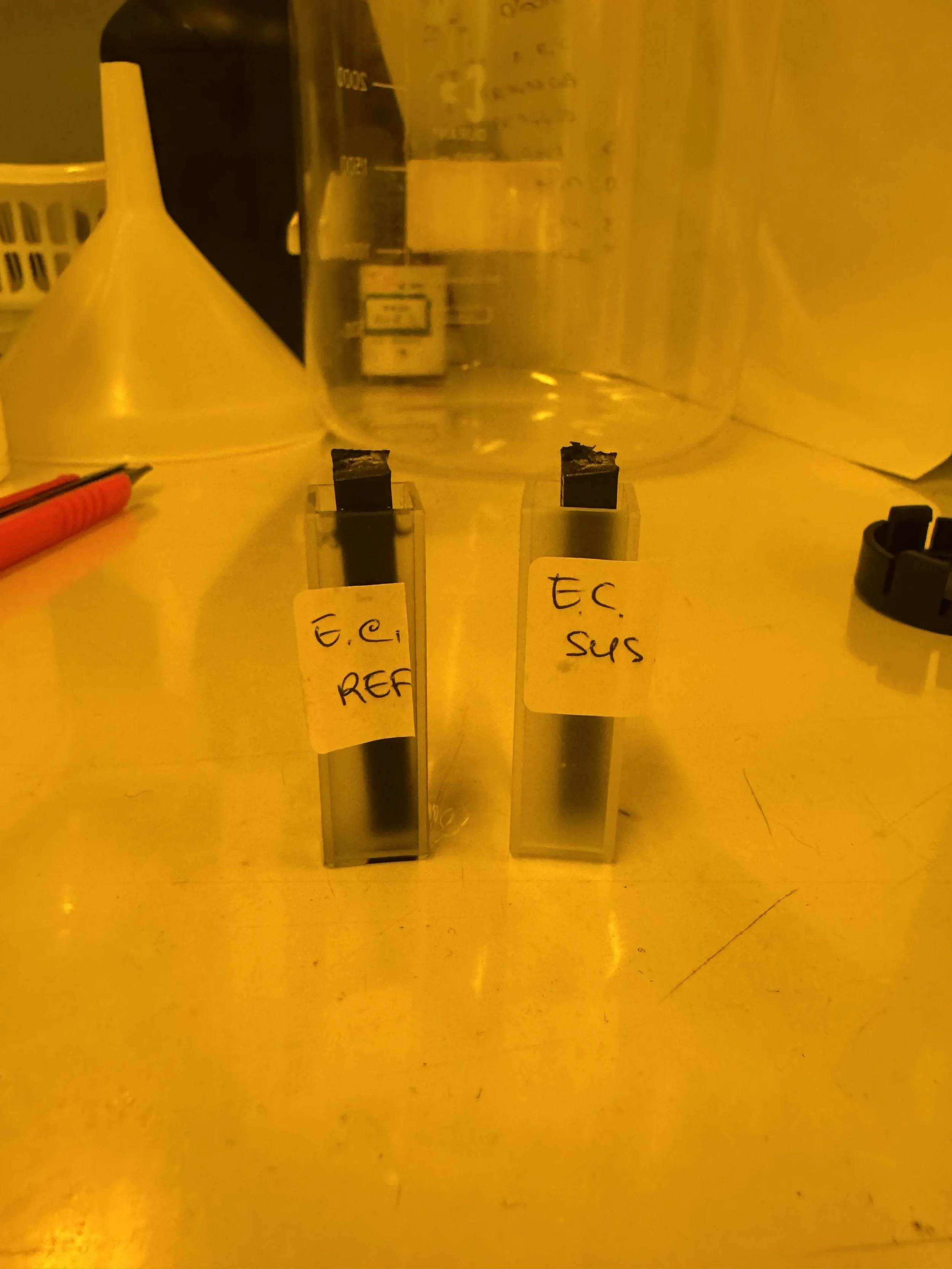

Chemical compatibility and metallurgic Root Cause was identified as below-standard anodized coating in critical locations.

Implementation & Outcomes

As it happens sometimes, the scope of this project was significantly bigger than expected, and the impact on the Products and engineering approach was profound.

On the Products level, we’ve implemented 4 major changes:

Mechanical redesign to the pre-heater’s resin path.

Introduction of advanced temperature control logics, implemented on the printer’s software in 3 phases.

Revised anodization requirements and test methods.

Introduction of improved resin compounds across most of the lineup.